Technical data about the Energiepark

-

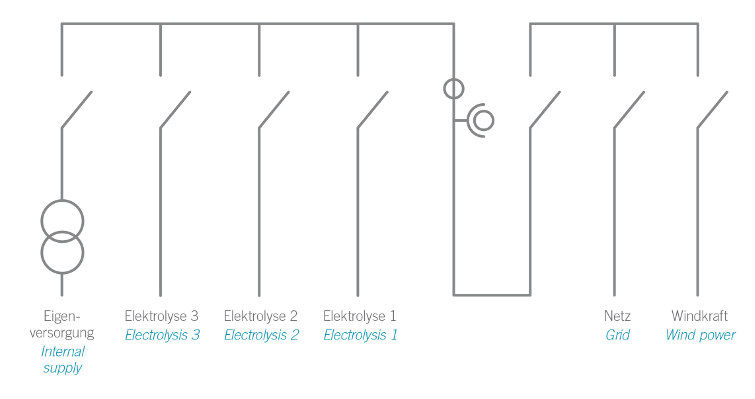

Electrical Grid Connection

Electrical Grid Connection

The power-to-gas system is directly connected to both the medium-voltage grid of Stadtwerke Mainz and an adjacent wind farm. The decentralized storage of electrical energy in times of high wind feed-in is used for the network integration of renewable energy and guarantees grid stability. The objectives include optimization of local load management with the help of flexiblised, wind power feed-in as well as the management of local grid bottlenecks through hydrogen storage systems.

-

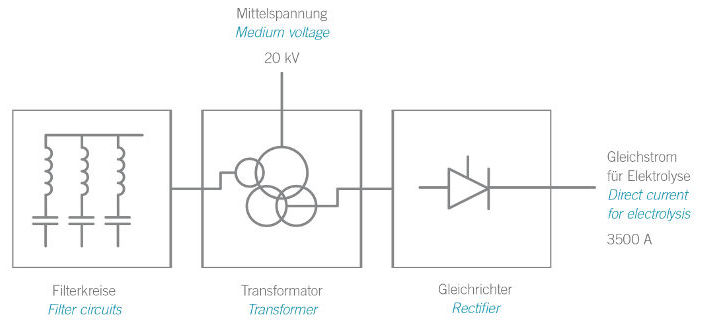

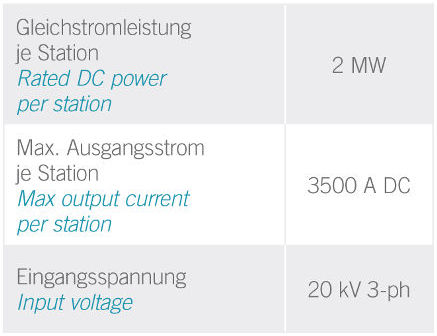

Direct Current Stations

Direct Current Stations

Three direct current stations generate the high direct current required for the electrolysis process. The electrical power required for this by each station are drawn directly from the medium voltage grid using GEAFOL cast-resin transformers. The current is inverted by industry-proven SINAMICS inverter cabinets. Unwanted high grid interference is prevented by an integrated multiple-stage filter circuit system.

-

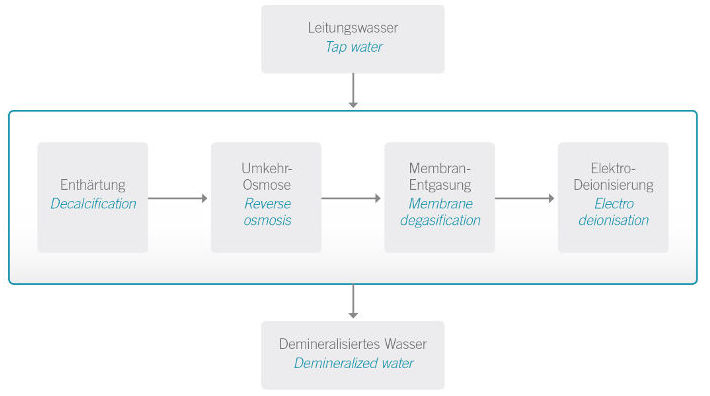

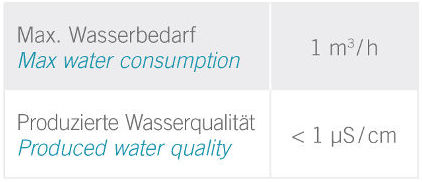

Water treatment plant

Water treatment plant

The electrolysis process requires demineralized water. To produce water with this level of very high purity, the water treatment plant draws out all the dissolved minerals contained in normal tap water over a number of stages. A buffer tank ensures a constant supply of water to the electrolysis process even during periods of downtime, for instance during maintenance work on the water treatment plant.

-

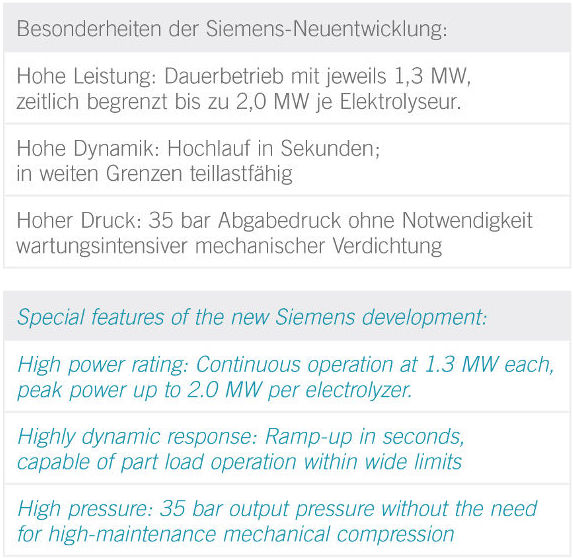

Electrolysis System

Electrolysis System

Three SILYZER 200 electrolyzers equipped with innovative proton exchange membrane (PEM) technology split water into hydrogen and oxygen using electrical direct current. The proton conducting membranes used in the electrolyzer cells keep the gases apart reliably and offer a high safety level, also thanks to the innovative cell design.

-

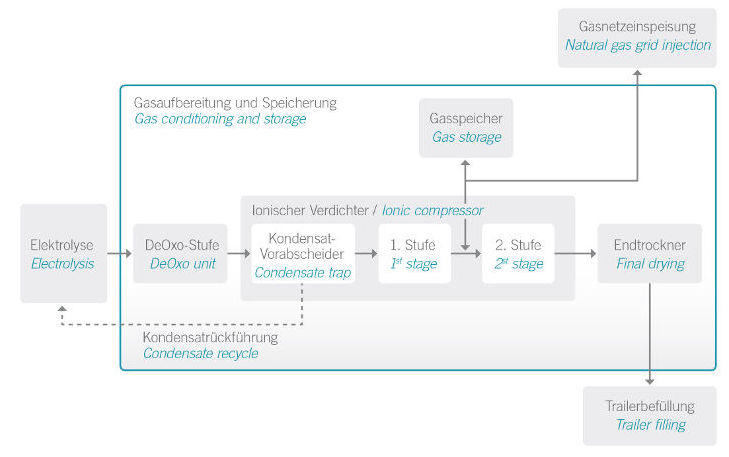

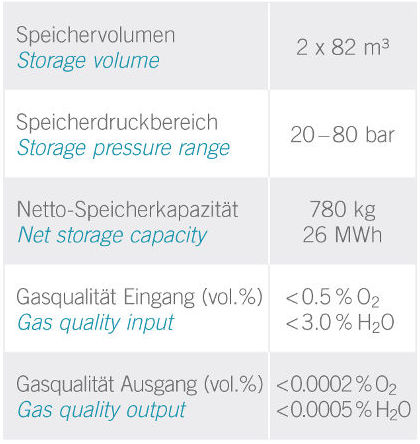

Gas Conditioning and Storage

Gas Conditioning and Storage

Raw hydrogen from the electrolysers is first passed through a catalyst to convert residual oxygen to water vapor. The major part of the moisture fraction is condensed before and after the compression and recycled back to the electrolyzer. The hydrogen is stored in the pressure vessels. From there, or directly from the first compressor stage, the gas can be delivered to the NG grid injection. Also, after running through the second compressor stage and the final drying based on temperature swing adsorption, it can be delivered to the trailer filling station.

-

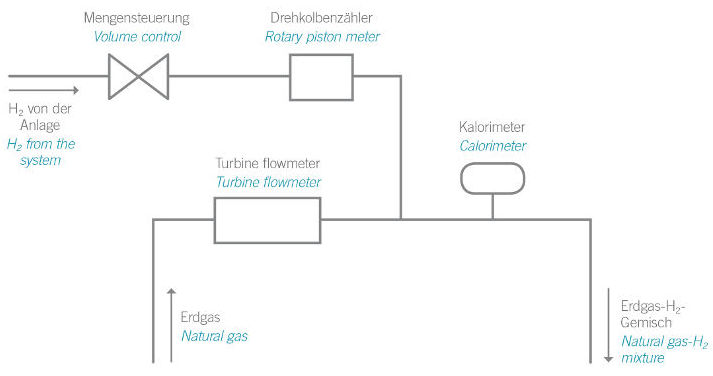

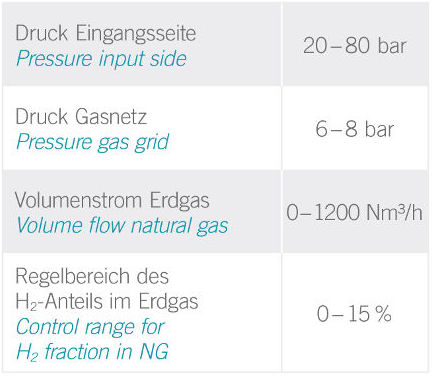

Hydrogen Natural Gas Grid Injection

Hydrogen Natural Gas Grid Injection

The hydrogen produced in the energy park can be injecteded into into the high-pressure natural gas grid of Stadtwerke Mainz. The admixing occurs in a stub line, which supplies the Mainz-Ebersheim district. This process replaces fossil natural gas. All applications connected to the natural gas network, such as heating systems, gas burners, thermal power stations and gas power plants can be partly supplied with the hydrogen generated. In addition, the enormous storage capacity of the natural gas grid can therefore be utilized for the energy from the power system.

-

Ionic Compressor

Ionic Compressor

The ionic compressor, an in house development by Linde, is the core component of hydrogen conditioning. An “ionic liquid” (a liquid salt) lubricates, cools and seals the hydraulically driven piston compressor, without adding any impuritues to the hydrogen. The unit has been designed for multivariable operation, including fast load changes and high efficiency at part load. With its two stages it can be used to feed both the storage vessels and the trailers. A further feature is the integrated drying of the hydrogen.

-

Trailer Filling

Trailer Filling

Here, the hydrogen is filled into trailers using a fully automated process.After the filling hose is connected to the trailer, its remaining contents are analysed. Then, the trailer is filled with hydrogen from the compressor. Purity, temperature and pressure are monitored continuously. After finishing the filling process, the filling hose is disconnected and transfer documents are printed. The trailer is ready for pickup and delivery of the hydrogen to refuelling stations or industrial consumers.

- Show Information

- Show Information

- Show Information

- Show Information

- Show Information

- Show Information

- Show Information

- Show Information

Please select a number for more information