Technology

The plant works with up to 6 megawatt electric power. This is enough to compensate capacity shortages in the distribution grid. In the future similar plants could work in various locations to stabilize the grid. The system, which will be built at “Energiepark Mainz”, will be the largest of its kind today.

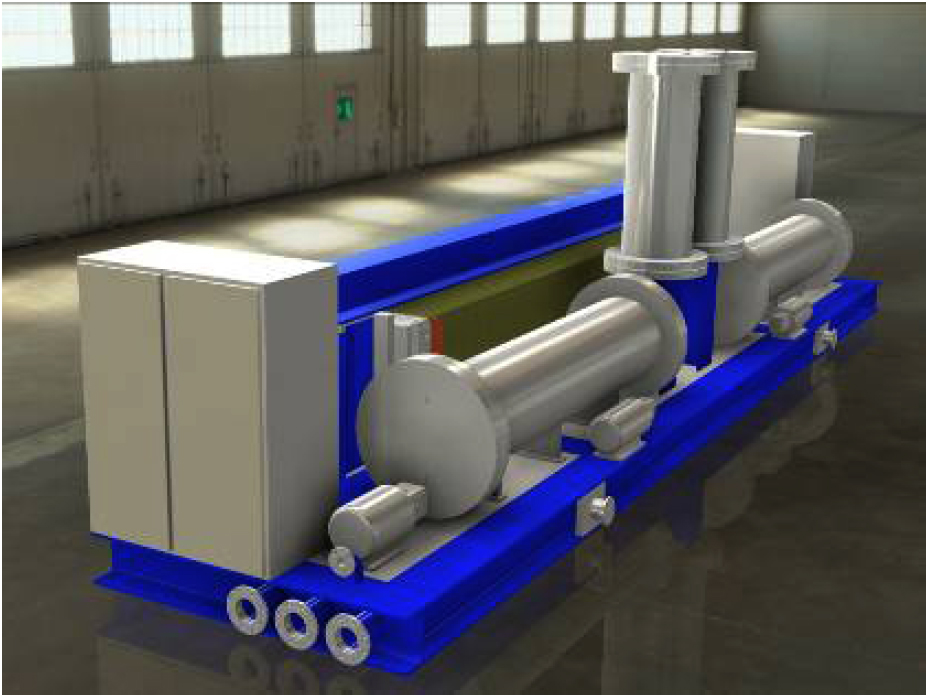

The central link between green power from wind energy and hydrogen are innovative hydrogen electrolyzers from Siemens. In the future, these will also be offered as a standard solution for large scale plants.

Electrolyzers use modern PEM-electrolysis technology (Proton Exchange Membrane). This enables a highly dynamic system operation, which is mandatory for a power supply from fluctuating renewable energy sources. At “Energiepark Mainz”, three of the described PEM-electrolyzers will be operated, with a peak performance of up to two megawatt each. The operation of PEM-electrolyzers in this performance category is a worldwide first, because until now PEM-based systems were only used for small scale hydrogen production.

Other essential system components include a two-stage ionic compressor, the gas feed, filling appliances and the switchgear. The “ionic compressor”, which was developed by Linde, compresses the produced hydrogen so that it can be filled into storage tanks, gas pipes and tank trucks. Until now this technology is used mainly for hydrogen fuelling stations. But it offers considerable advantages for “Energiepark Mainz” as well, especially its operational flexibility, which matches perfectly with the PEM-electrolyzers and the available renewable energies.